1.Building strength with simplicity:

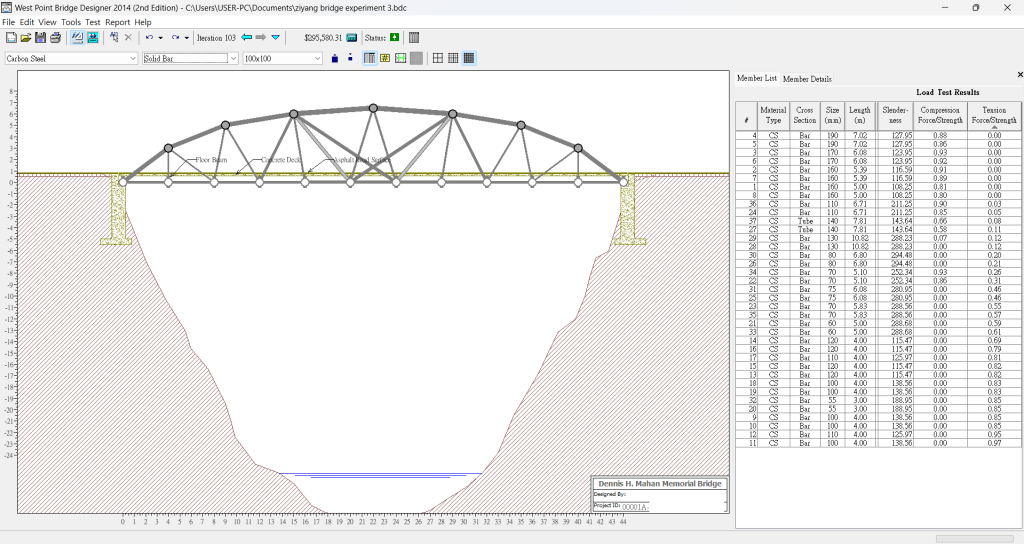

When I first clicked into the “Five Types of Bridges PDF” I start having a picture in my mind of how my bridge will look like. And ofcourse I clicked run right away, and it shows this :

So i had to keep adding material to make it strong enough, it took a while for me to successfully run it, but this happened:

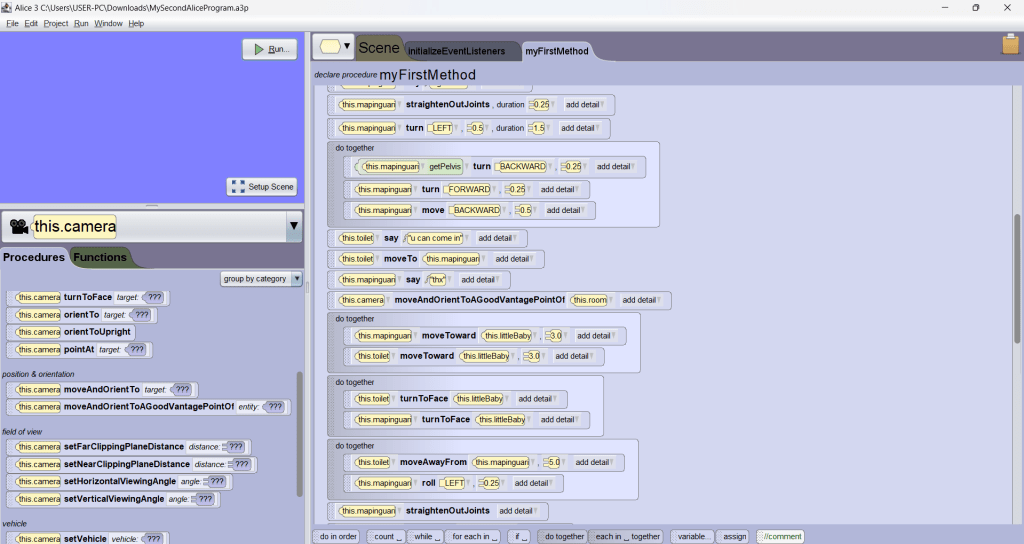

I went back to the PDF and carefully looked at the Truss Bridge section, and noticed that repetitive triangular framework is what’s needed that allows the structure to handle weight and pressure incredibly well. So I made a new project and started over by choosing the Truss Bridge template for a reference, and by just connecting the dots with lines and thickening some compressed lines, and finally after lots of runs, it worked!

2.Challenges of lowering the Price:

But when I saw my peer’s work i thought mine was nothing some of theirs are already under 200K, which is where i can’t even reach even at the end of this project I’ve got a cheap bridge of 295,580.31USD. Before that I kept working from almost a price of 500K to under 300K. During that time i had found that Truss bridges use a clever balance of tension and compression forces—making them strong, stable, and ideal for supporting heavy loads across long spans.

3.Tension Vs Compression, Solid Bars VS Hollow Tubes:

When I was just wondering why my lines are not capable of compression parts, I heard Tr.Robert talking about compression VS tension relates to hollow tubes VS solid bars. So I looked into the PDF again and I learned- “Truss bridges use a clever balance of tension and compression forces—making them strong, stable, and ideal for supporting heavy loads across long spans.” So I changed a lot of my lines to hollow tubes from the compression/ tension forces chart.

And this is before adding hollow tubes:

And this is after adding hollow tubes:

As you can see:

Hollow tubes are great under compression. Since compression tries to squish the material, a hollow tube can resist buckling better because of its shape—it spreads the force around the outside. They’re also lighter and cheaper, which helps reduce the overall cost.

Solid bars, on the other hand, are better for tension. Tension tries to pull the material apart, and a solid bar gives you more strength across the entire piece. Since the material is consistent all the way through, it’s less likely to snap or stretch too much under pressure.

This transformation from an all solid bar truss bridge to a mixed(solid bar and hollow tubes) truss bridge had made my bridge way cheaper price before adding is 311,556.97USD, while the price after adding is 295,508.31USD.

4.The Power of Triangles:

One interesting fact I found when i was walking around is that people are struggling on their bridge design because of the bridge type they chose so I went back to my seat and checked out the PDF again. What I’ve noticed is that unlike beam or arch bridges, truss bridges rely on triangular units to distribute weight efficiently. This structure makes them strong, lightweight, and perfect for longer spans without needing tons of material. So I think I was really lucky that I chosen Truss Bridge.

“What makes truss bridges special is how they balance forces—the triangles spread out the tension and compression so no one part of the bridge takes all the stress. This lets the bridge stay strong while using less material than other types.” according to the PDF, I’ve noticed that triangles are a really good shape for an inside support of a bridge, which gives me inspiration me to continue working on my Truss Bridge design.

5. The Final Experiment of my Bridge Design Project:

final bridge design picture:

The price of my bridge design:

6. Summary of what I’ve learned:

Throughout the project I’ve learned many facts about Truss Bridges, such as “the power of triangle” and “Tension Vs Compression, Solid Bars VS Hollow Tubes”, this experience might not have only been a computer science lesson but also an engineering and physics lesson.

7. Final thoughts about this project:

Honestly, this project was way more interesting than I expected. It wasn’t just about building some random bridge—it was about figuring out how physics works, where I messed up, and how to fix it. Infinite trials and errors. I liked seeing how small changes made a big difference, especially when it came to cost and strength. It kind of made me realize how much thought goes into things we see every day but never really think about. Overall, it was actually a fun way to learn about engineering.

8. Bridge Designer Versions:

I can’t find a website where I can install the Bridge Designer 2014 Software, but I do and did download the Bridge Designer 2016 Software, so I couldn’t open the previous (cheapest one) I’ve made in school, which is very tragic for me because I worked so hard on that one.